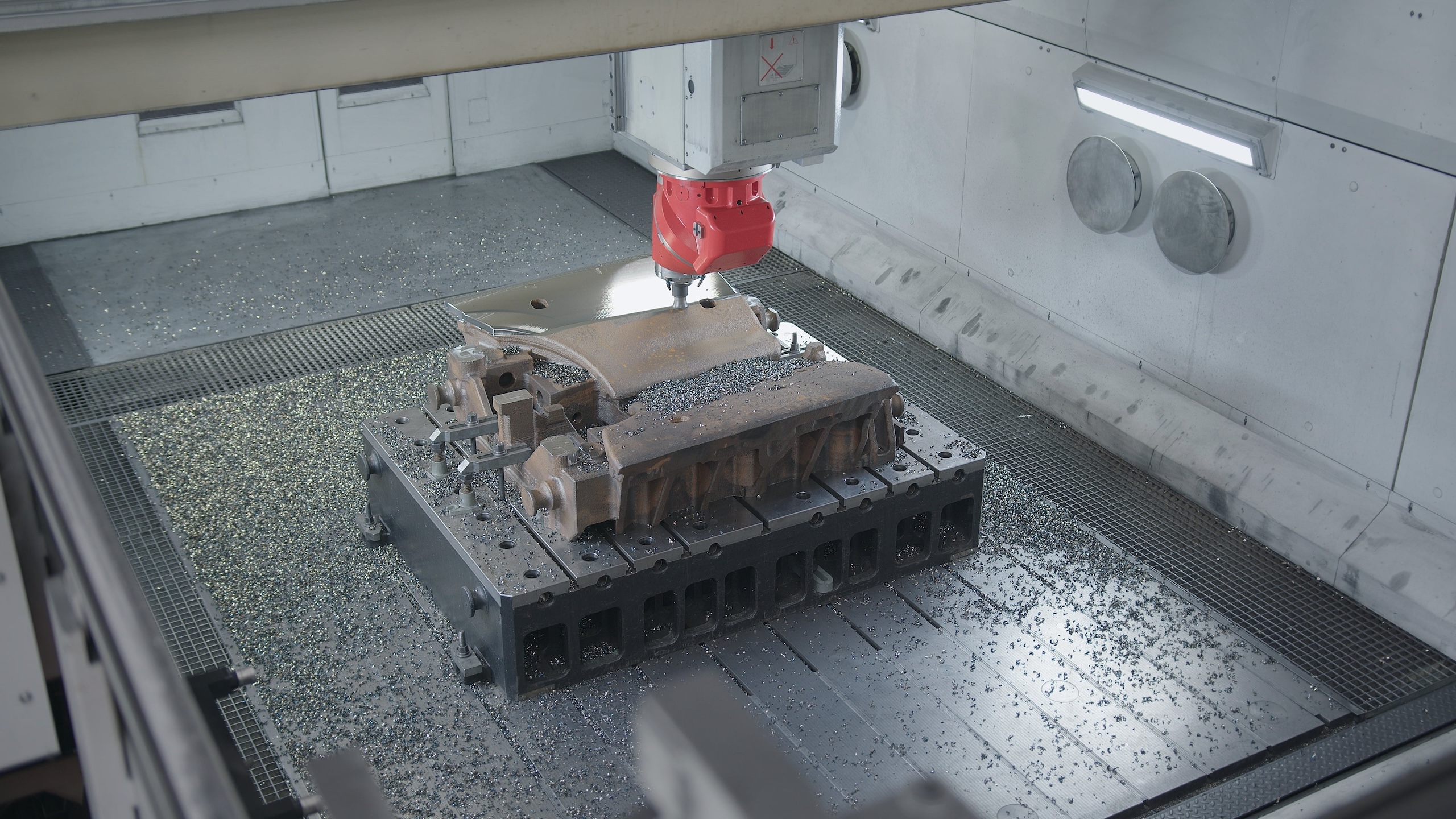

Assembly & verification

We are testing, you are manufacturing.

All molds are thoroughly tested on our side — so they perform perfectly on yours, right from the start.

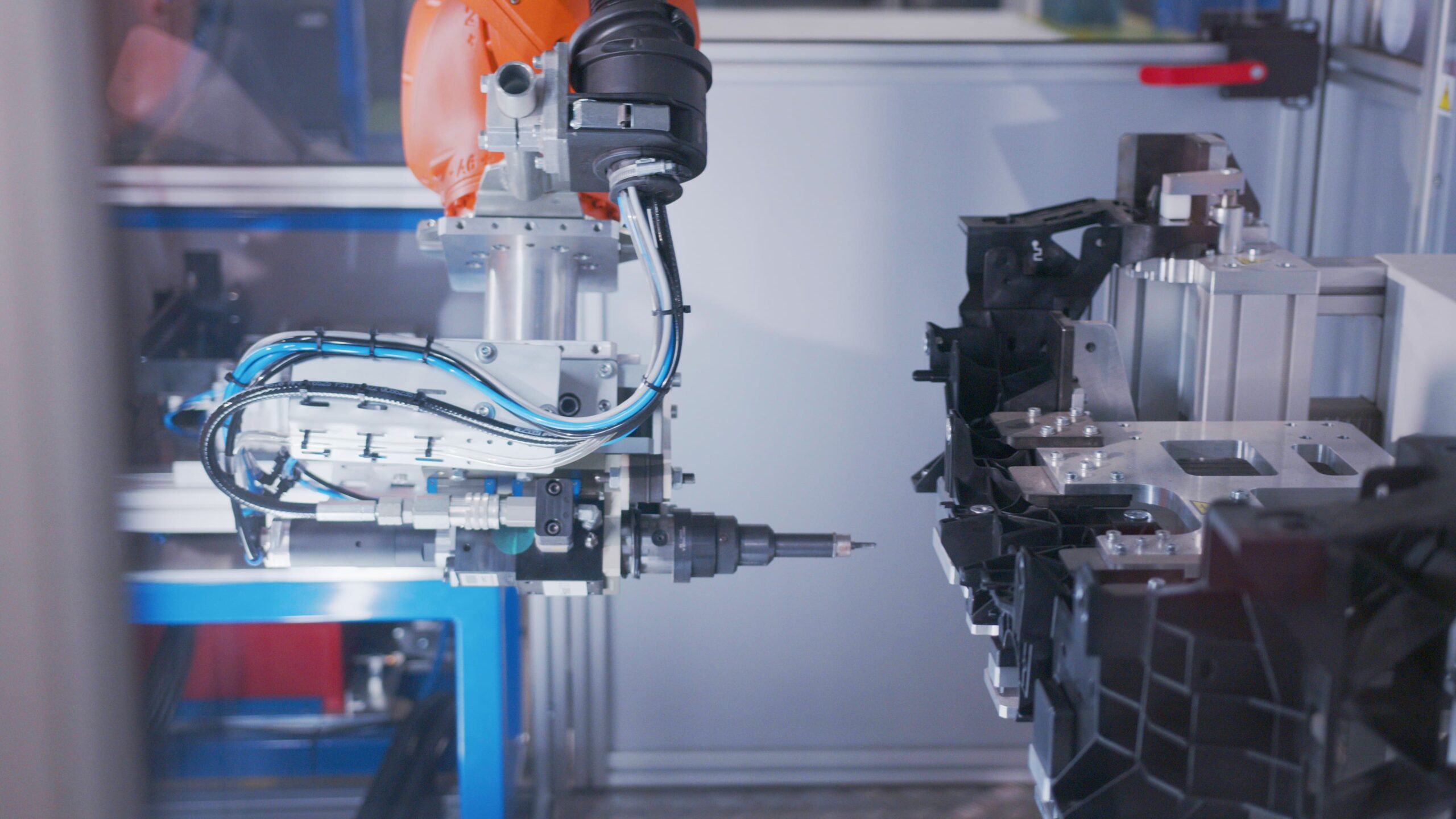

Thoroughly planned smart engineering is the foundation of every precise mold. At HAJDIK Tooling, we design injection molds with a focus on maximum performance efficiency, durability, and easy maintenance. Every mold design is developed in a 3D environment where material properties, cooling methods, and the specific requirements of the final molded part are taken into account.

Beyond new mold designs, we provide reverse engineering services – reconstructing molds from existing parts, optimizing their geometry, and preparing them for efficient production. By working hand in hand with production and engineering, we perfect every detail to deliver seamless performance — right on the first try.

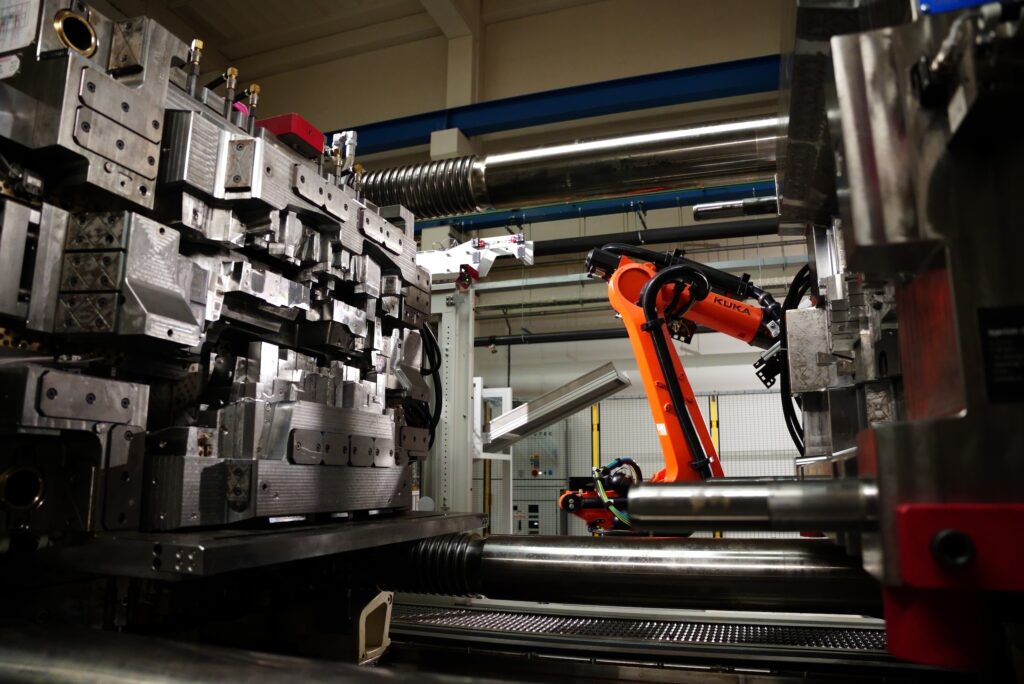

High-Quality Mould from China Under Our Supervision

As part of the HAJDIK family, the HAJDIK China project office oversees mould production on-site at carefully selected Chinese partners.

HAJDIK Specialists – Your Guarantee of Quality

In China, we have an experienced team:

- Yin Ping, Project Manager with over 15 years of experience

- Wan Yonghai, Tooling Specialist supervising assembly and the technical aspects of production

We personally monitor every project directly on-site. We select the right supplier, conduct audits, check the materials used, oversee the assembly process, and control sampling. Thanks to this, we can guarantee that the mould meets customer specifications – and that all of its components are original and repairable in Europe.

Complete Process Under Control

The delivery process of an injection mould takes place in several stages: Based on the customer’s requirements, we select a verified tool shop in China where our specialist supervises the mould assembly. After the first sampling and functionality check, the trial parts are sent to the Czech Republic for check. This is followed by optimization in China and a second sampling, this time with an automation test. Once approved, the mould is shipped to Olšany, where we test it again. If necessary, change management is carried out. The final mould and samples are then delivered directly to the customer’s production line.

The entire process, from initial request to finalization, is managed through our sales department in the Czech Republic.

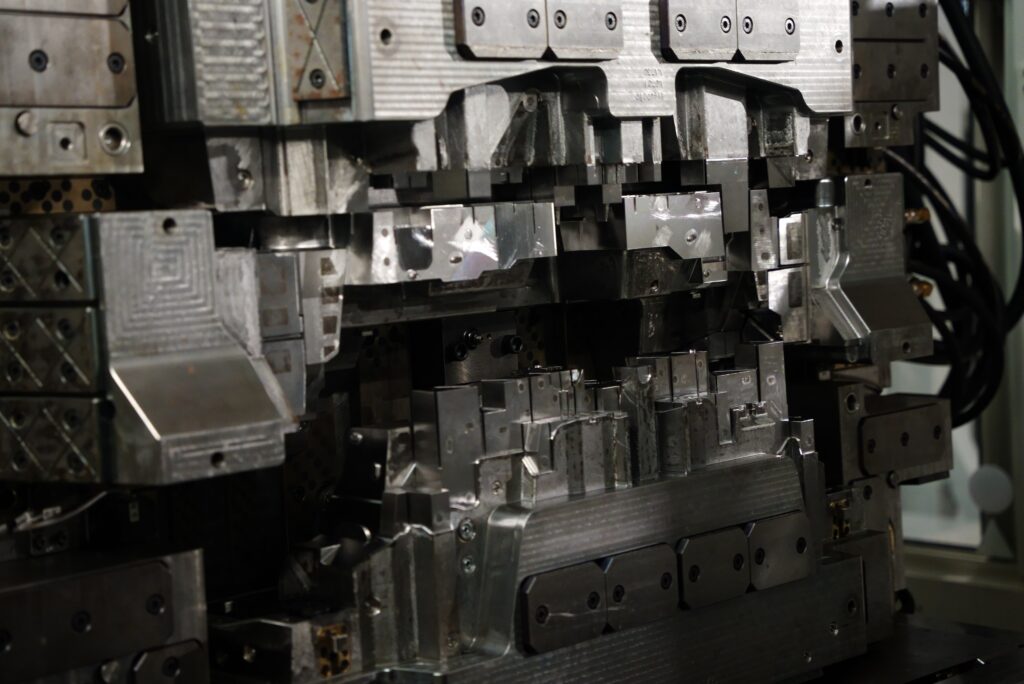

Guarantee Without Compromise

- All moulds are produced in a controlled process according to our specifications.

- Materials come from steelworks approved by us.

- Every tool shop undergoes an audit.

- Sampling, trial part inspection, and final approval are always carried out under our supervision – whether in China or at our facilities.

Thanks to this combination of Czech know-how and careful oversight in China, we provide customers with an efficient, reliable, and fully serviceable solution.

When the mould arrives at your press, you know it’s ready.